Choosing the right glass insulator ensures optimal performance, safety, and durability in electrical systems. High-quality insulators, known for their dielectric strength, enhance reliability in power grids and surge protection devices. Recent innovations in materials and manufacturing processes have further improved their efficiency and sustainability. Consulting a reliable glass insulator manufacturer, like CECI gridinsulators, helps you tailor solutions to meet specific needs.

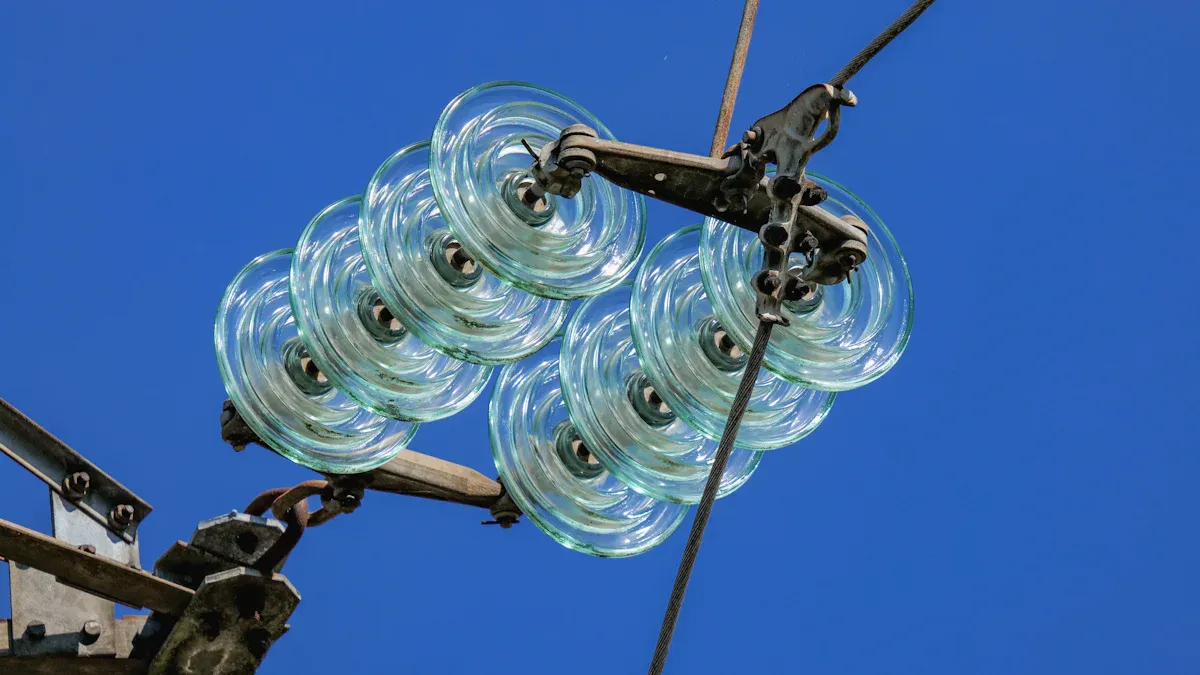

Glass insulators are specialized components used in electrical systems to prevent the flow of unwanted current between conductive parts. They are made from toughened or annealed glass, which provides excellent dielectric strength and mechanical durability. These insulators are critical for maintaining the safety and efficiency of power transmission and distribution networks. Their transparency also allows for easy visual inspection, making them a preferred choice in many industries.

Recent advancements in energy infrastructure have increased the demand for glass insulators. For instance, India’s national grid expansion requires millions of these insulators annually. Similarly, offshore wind farms, like the UK’s Dogger Bank Wind Farm, rely on glass insulators to connect turbines to mainland grids. These examples highlight the growing importance of glass insulators in modern energy systems.

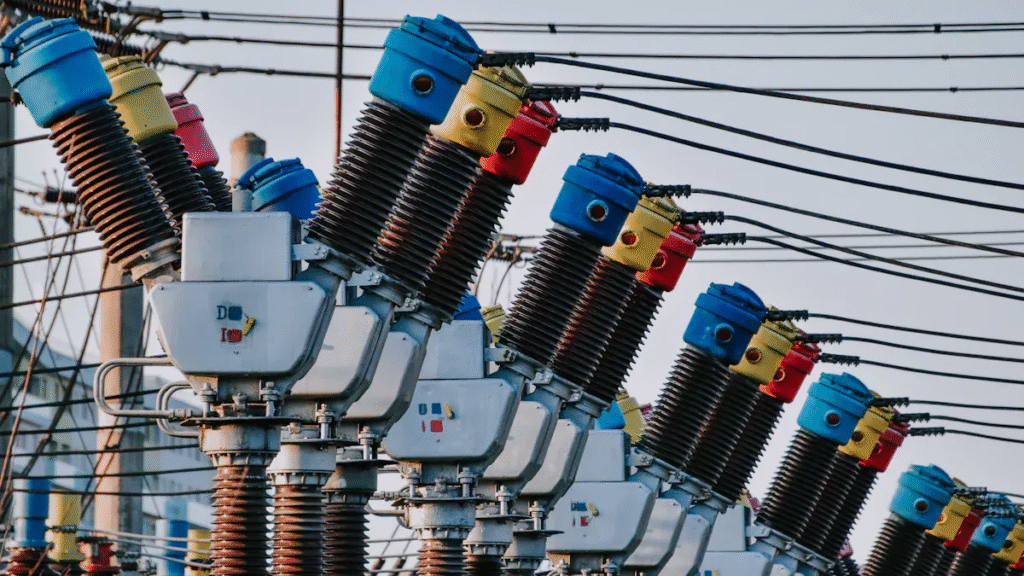

Glass insulators come in various types, each designed for specific applications. The most common types include:

Each type serves a unique purpose, ensuring that electrical systems operate efficiently and safely.

Matching the right glass insulator to your application begins with understanding the specific demands of your system. Different applications, such as power transmission, industrial operations, or renewable energy systems, require insulators with tailored designs and properties. For instance, high-demand environments like heavily polluted areas often necessitate specialized insulators. Open-profile designs improve self-cleaning capabilities, while RTV silicone coatings enhance performance and reduce installation risks. A study spanning 15 years highlighted the importance of regular inspections and maintenance strategies in such challenging conditions. These insights emphasize the need to evaluate your operational environment and choose insulators that align with your system’s unique requirements.

When selecting insulators for high-voltage systems, suspension insulators are often the preferred choice due to their ability to handle significant mechanical stress. On the other hand, low-voltage applications may benefit from pin-type or shackle insulators, which are cost-effective and compact. By identifying the specific needs of your application, you can ensure optimal performance and longevity.

Environmental factors play a critical role in determining the type of glass insulator you should choose. Outdoor installations, especially in polluted or coastal regions, expose insulators to harsh conditions like salt, dust, and industrial contaminants. These factors can compromise the insulator’s performance if not addressed during the selection process. International standards, such as IEC/TR 60815 and IEC/TS 60815, provide valuable guidelines for selecting insulators in polluted environments. Utilities like Eskom have successfully applied these standards to dimension outdoor insulators for challenging conditions.

In addition to pollution, temperature fluctuations and humidity levels must also be considered. Glass insulators with hydrophobic surfaces, such as those coated with silicone, perform well in wet environments by repelling water and reducing the risk of flashovers. For installations in regions with extreme temperature variations, insulators must undergo thermal shock testing to ensure durability. By accounting for these environmental factors, you can select insulators that maintain reliability and safety under varying conditions.

The performance of a glass insulator depends on its ability to meet both electrical and mechanical standards. Key performance tests, such as the steep-front puncture test and residual mechanical strength test, assess the insulator’s dielectric strength and mechanical durability. These tests ensure that the insulator can withstand high voltages and mechanical loads without failure. For instance, the ultimate tensile test verifies the insulator’s ability to handle conductor tension, while RIV testing evaluates the quality of the pin cavity design and cement used.

Industry benchmarks, such as IEC 60168 and ANSI C29.1-C29.12, outline the general mechanical and electrical performance requirements for glass insulators. ASTM D149 further specifies the dielectric breakdown voltage, ensuring that the insulator can handle the electrical demands of your system. A project evaluating insulators of varying quality revealed the importance of expanding test requirements to include RIV measurements at different voltage levels. This approach minimizes risks and ensures the insulator’s long-term reliability.

By prioritizing performance requirements during the selection process, you can ensure that your glass insulators meet the demands of your application while adhering to industry standards.

Selecting a reliable manufacturer is critical for ensuring the quality and performance of glass insulators. You should evaluate manufacturers based on several criteria:

CECI gridinsulators exemplify the advantages of working with a trusted glass insulator manufacturer. Their commitment to quality and innovation ensures that their products meet industry standards and exceed performance expectations. By leveraging advanced technologies, CECI gridinsulators provides insulators with superior dielectric strength and mechanical durability. Their focus on sustainability aligns with global energy trends, making them an ideal partner for modern infrastructure projects.

Regulatory compliance remains a cornerstone of their manufacturing process. CECI gridinsulators adheres to stringent safety and efficiency standards, ensuring their insulators perform reliably in challenging environments. Choosing a manufacturer like CECI gridinsulators guarantees long-term benefits, including reduced maintenance costs and enhanced system longevity.

Room 1502, NO.12, Shangwu Waihuan Road, CBD, Zhengzhou, China

Room 1502, NO.12, Shangwu Waihuan Road, CBD, Zhengzhou, China

+86-18937178812

+86-18937178812

sales@gridinsulators.com

sales@gridinsulators.com

WhatsApp us