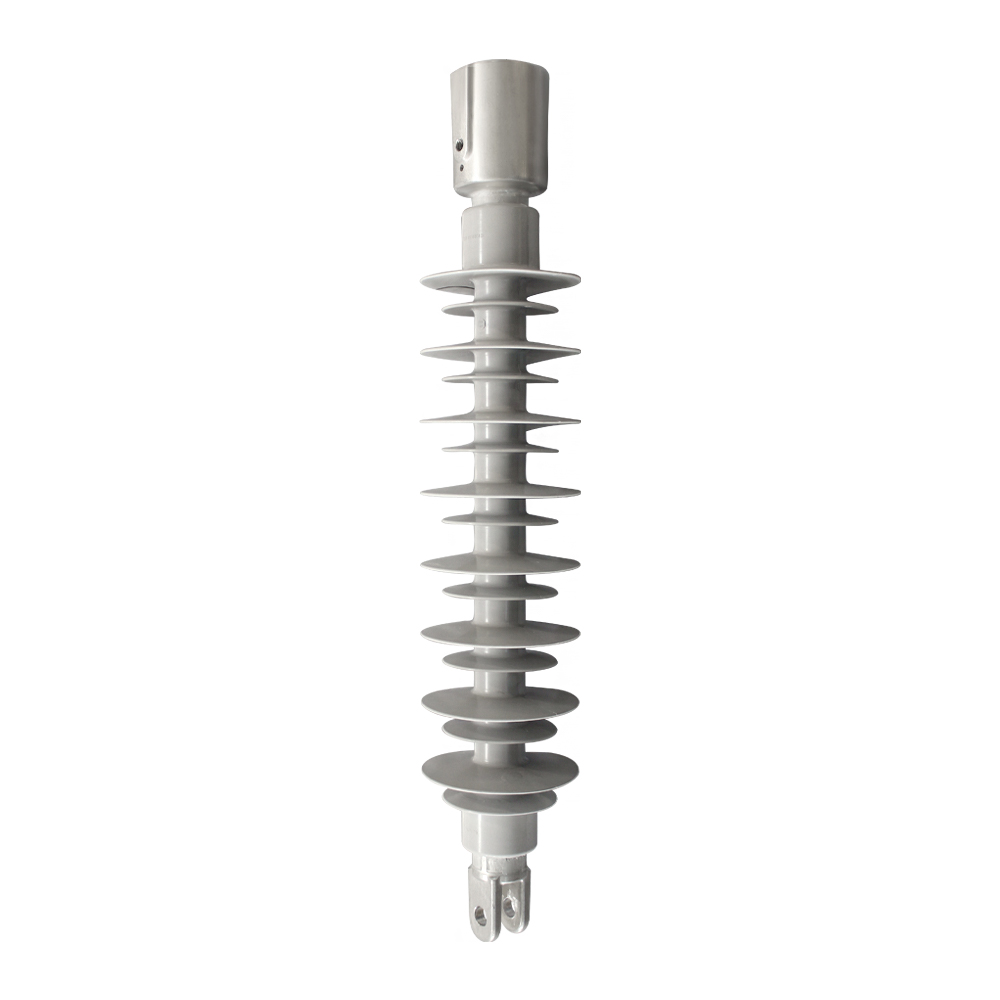

Composite station post and line post insulators, integral components of power transmission systems, feature a fiberglass reinforced polymer (FRP) core and a silicone rubber housing, providing distinct advantages over conventional porcelain insulators. Their main strengths lie in superior mechanical resilience, enabling them to withstand extreme weather conditions and be deployed in longer strings, potentially reducing support structure requirements. Additionally, these insulators exhibit excellent pollution resistance, repelling dust and salt deposits, making them well-suited for harsh environments like coastal areas.

Further benefits include their lighter weight, facilitating easier handling and installation, and an extended service life, resulting in reduced maintenance needs and enhanced durability against vandalism or accidental impact. This, in turn, leads to significant cost savings over the lifespan of a transmission line.

In terms of applications, composite insulators find use in various high voltage transmission and distribution systems, including substations and power lines. Their suitability for areas with harsh weather or high pollution levels, as well as for long-distance transmission lines requiring fewer support structures, underscores their versatility and cost-effectiveness. Overall, composite station post and line post insulators stand out for their superior mechanical strength, pollution resistance, and longevity, making them ideal for diverse high voltage applications, especially in challenging environments or for extended transmission lines.

Shed connected with core by integral foring

Acid resistant , hight temperature resistant of epoxy fiberglass core

Metal end fittings , core and sheds connected by new crimping process

Hot galvanization and technology of rareearth aluminum coating to avoid coating